About Dhiraj Industries

Dhiraj Industries, a progressive company with sound industrial experience of over 35 years in metal processing technology, is engaged in the manufacturing of welded stainless steel pipes & tubes, to meet the growing demand for critical applications from a wide spectrum of industries.

Dhiraj industries incorporates the latest process & techniques and is equipped with the most sophisticated plant & equipment to produce excellent quality pipes & tubes conforming to all international standard specifications and meeting exact requirements of end users.

Manufacturing Process

Manufacturing of stainless steel pipes & tubes commences with formation of welded mother pipes / tubes on custom designed sophisticated tube mills where stainless steel strips are slit to precise widths and are continuously set into a tubular shape and welded by Tungsten – Inert Gas (TIG) welding. The welding is highly precise and completely automated whereby the edges of the strips are headed and fused together under protective atmosphere of argon through a non-consumable electrode without the addition of any filler. Welding is continuously monitored by precision electronic devices to ensure perfect arc stability and direction in a magnetic field.

In the following sequence to welding, a continuous bead hammering / surface grinding is performed to smooth out weld bead and achieve perfect bore. The tube is then cut to desired length employing a flying cut off machine on the tube mill line.

Depending on the final tube sizes and specification, the tubes are then subiected to series of operations namely picking, coating, drawing, solution annealing in a continuous & temperature controlled furnace, final picking and passivation, followed by thorough inspection and dispatch.

Applications

Dhiraj Industries manufactured pipes & tubes are suitable for critical applications in the fields of railways, automobiles, chemicals, petrochemicals, sugar, dairy, fertilizers, solvent extraction, breweries, oil processing, pharmaceuticals, textiles, paper & pulp, synthetic fibers, pesticides etc.

Our pipes & tubes are also versatile in application such as heat exchangers, heating coils, condensers, evaporators, fluid piping, digesters, decoratives, furniture & structural etc.

Dhiraj Industries manufactured pipes & tubes are supplied duly, per quality assurance practices to comply with the standard specification & customer’s requirements. A standard quality control plan is followed to carry out inspection at various stages of manufacturing process and all products are subject to hydrostatic, mechanical, visual and dimensional tests to ensure complete weld integrity and homogenization of the weld areas.

QUALITY CONTROL & PRODUCT RELIABILITY

- Visual Testing

- Eddy current testing

- Hardness Testing

- Hydrostatic Testing

- Micro Structure Examination

- Chemical Laboratory Facilities

- Physical Testing

ENQUIRY CHECKLIST

When making enquiry or placing an order, the following information is solicited from customers for S.S. Pipes & Tubes

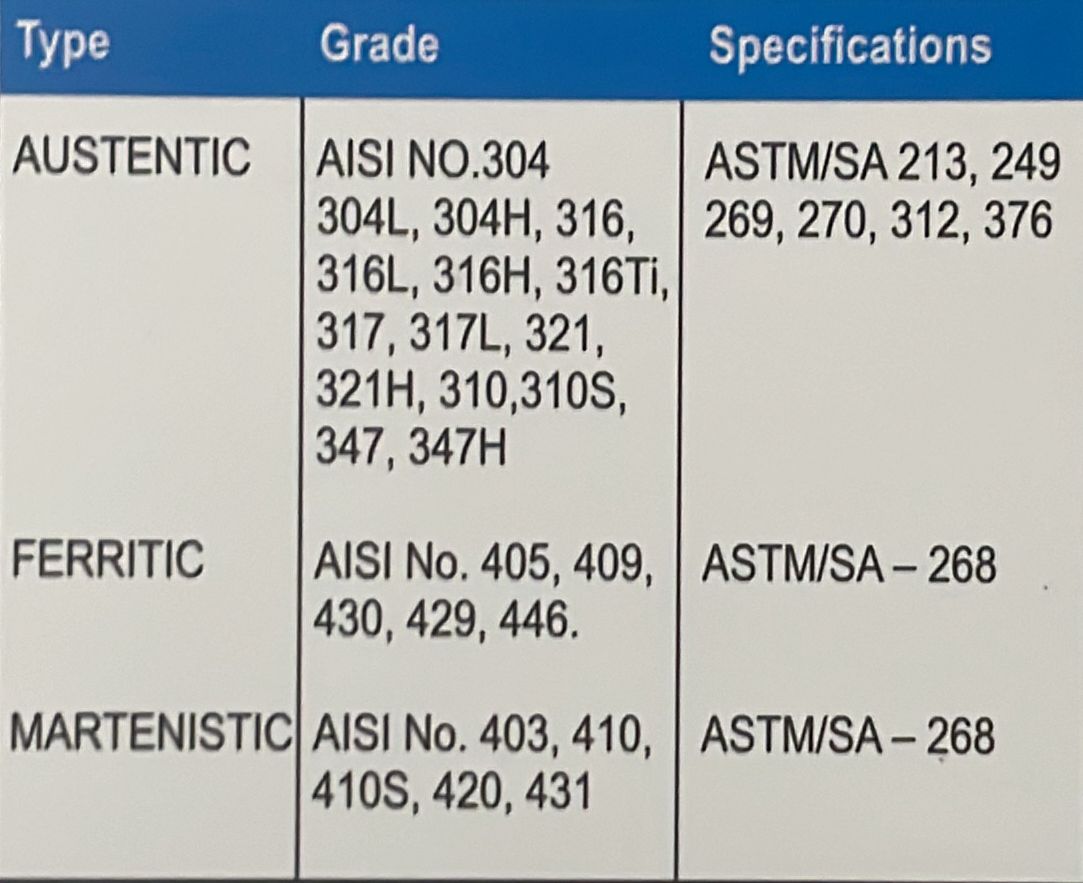

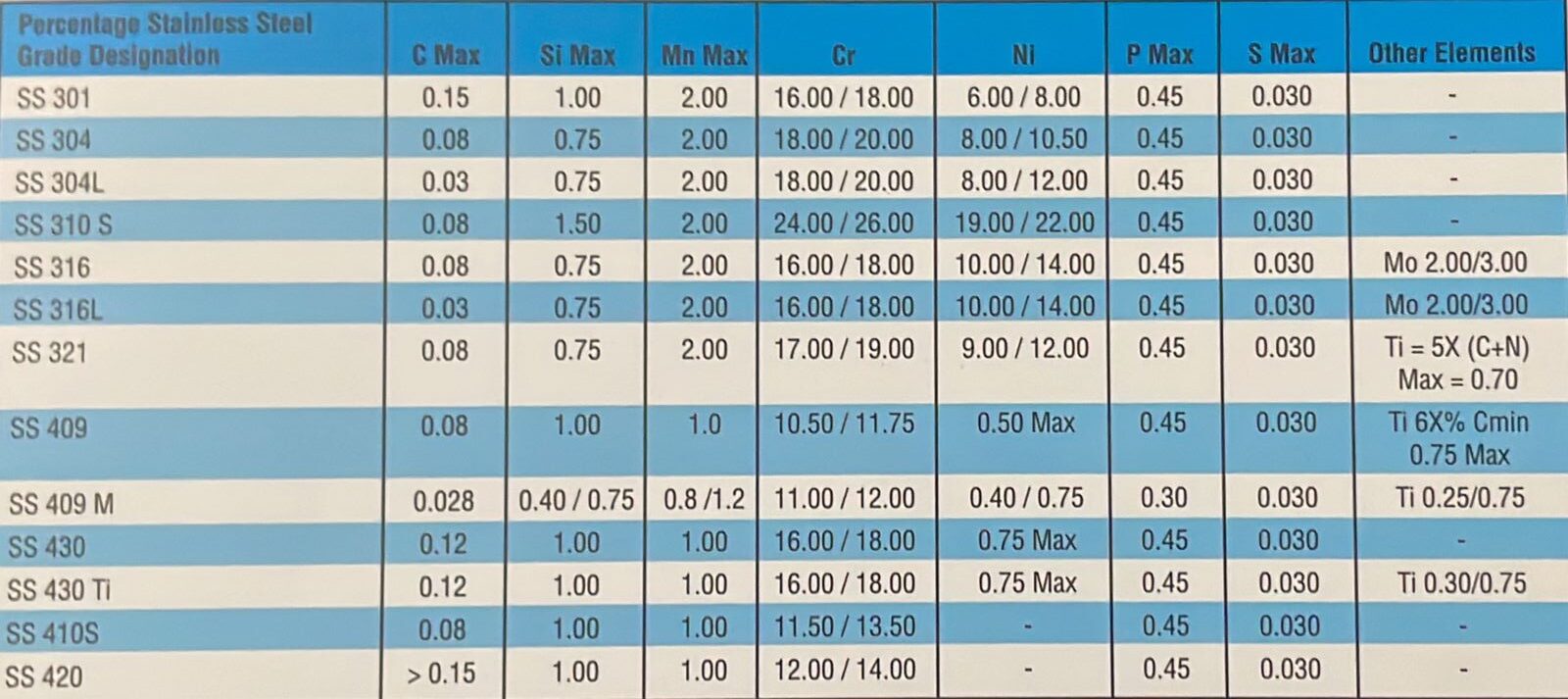

a) Material Grade i.e. AISI 304, AISI 316 etc.

b) Manufacturing Standard: ASTM

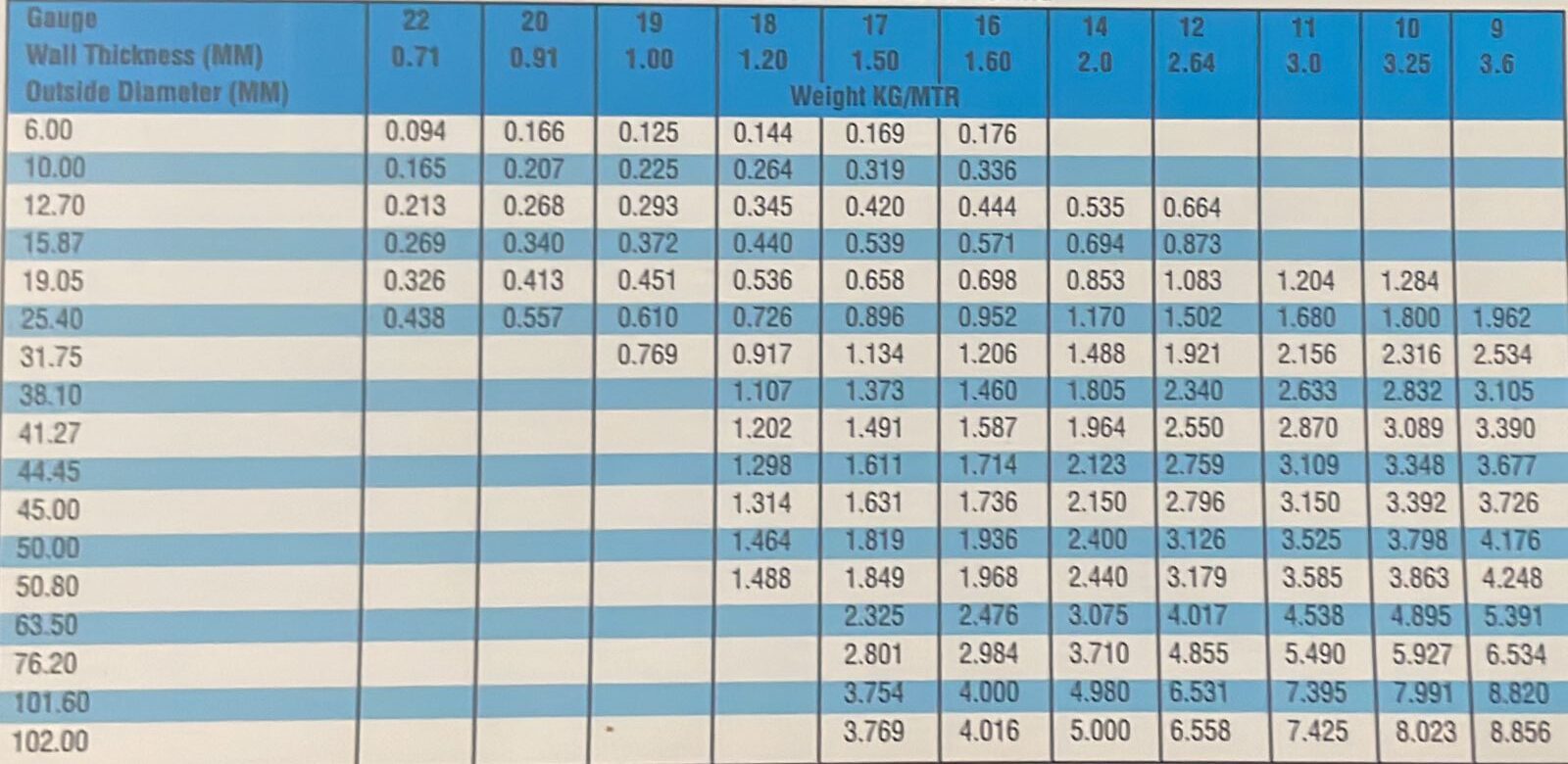

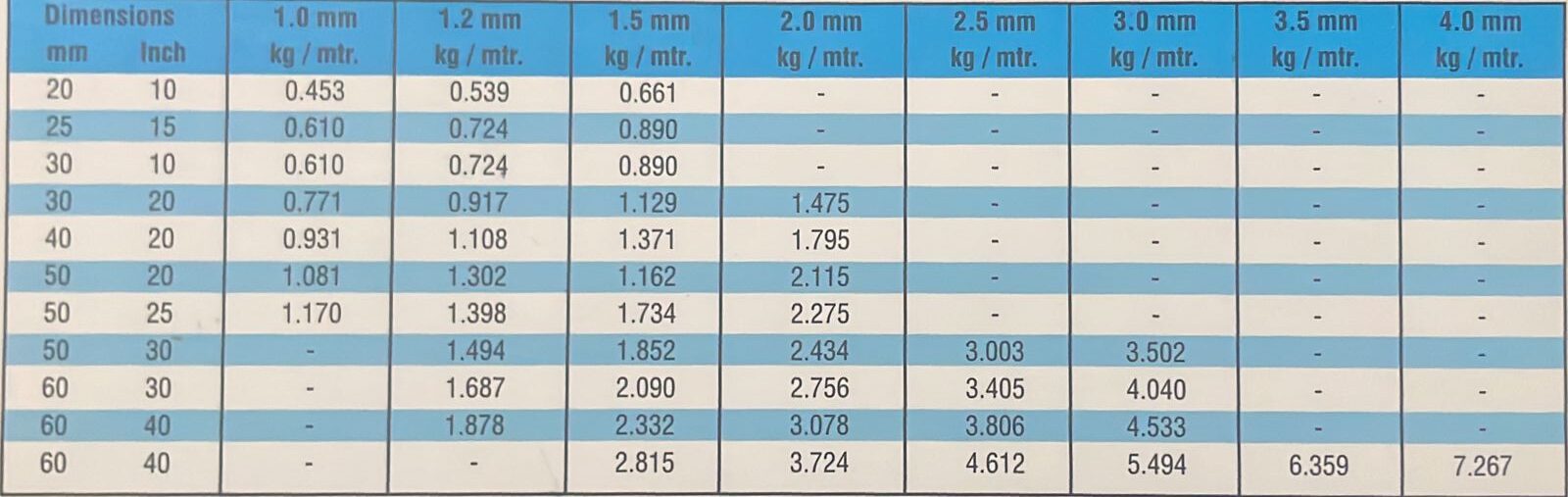

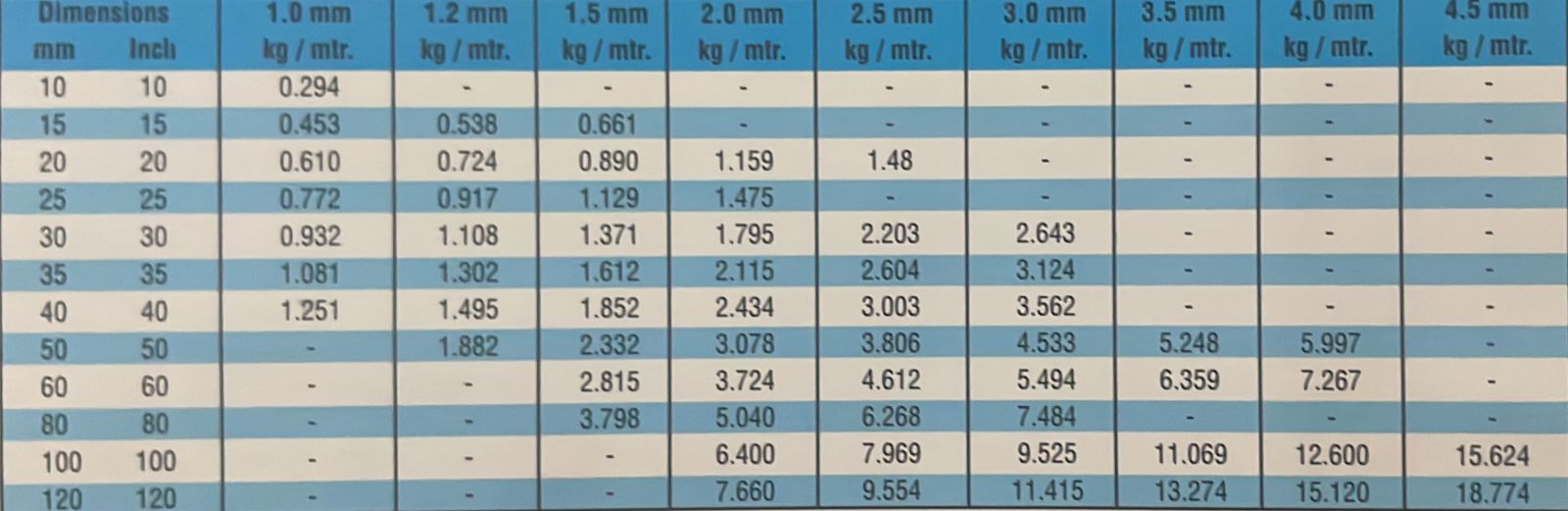

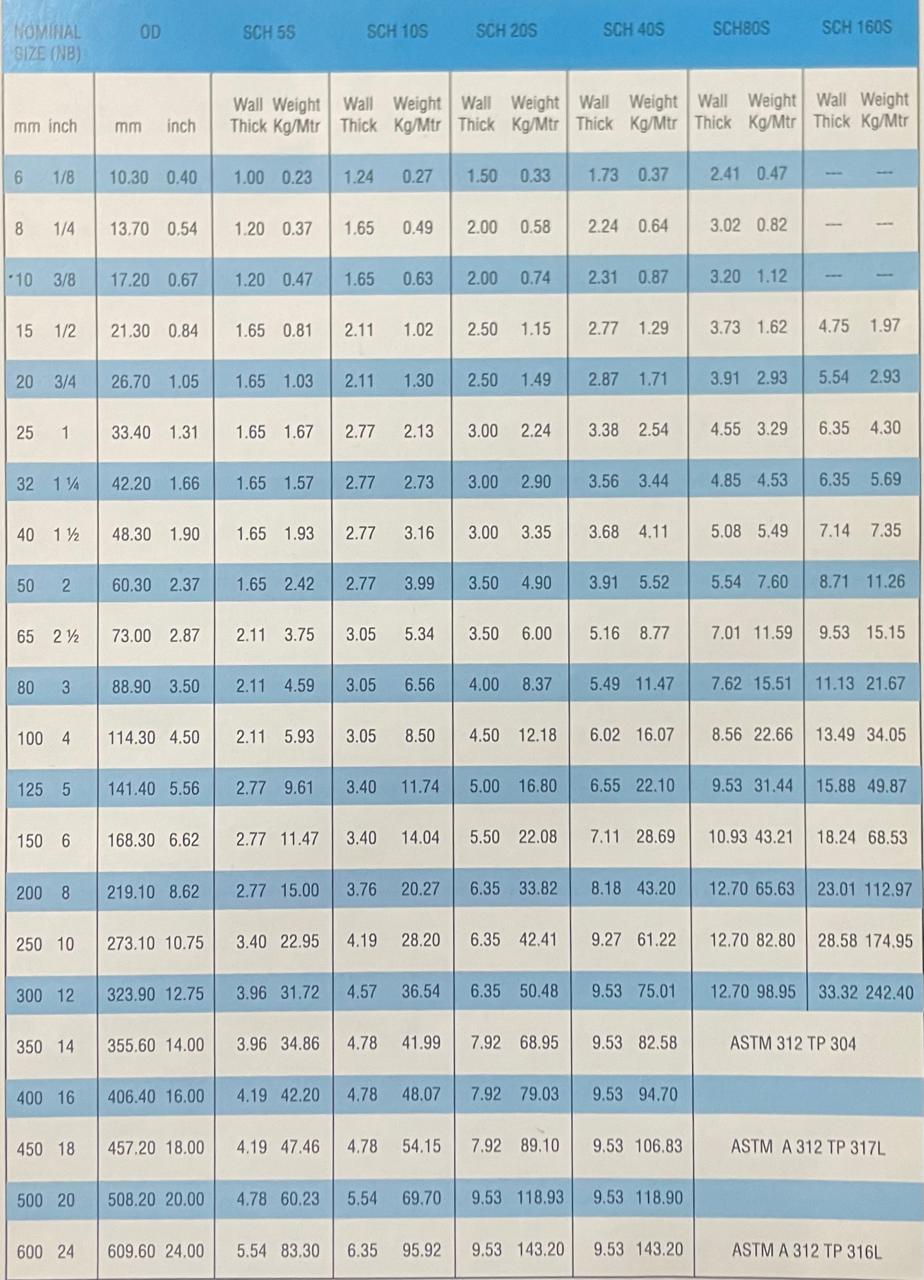

c) Size i.e. outside diameter, wall thickness or nominal pipe size & schedule no., length etc.

d) Quantity required meters or numbers

e) Finishing required.

f) Details of application

B) Quality of tubes or pipes i.e. welded, drawn etc.

Addreses

Office: 512 Swastik Chambers, CST Road, Chembur, Mumbai 400 071, India

Manufacturing: W67A MIDC Badlapur, P.O. Kulgaon, Thane – 421503, Maharashtra, India